Understanding Cardboard Cores Their Uses Benefits and Applications

Cardboard cores are often overlooked yet essential components in various industries. These cylindrical structures are primarily made from recycled cardboard, providing an eco-friendly solution for manufacturers and consumers alike. According to industry expert Sarah Johnson, “The versatility of cardboard cores makes them indispensable in packaging and construction.” This highlights their significance beyond mere support roles.

Various applications for cardboard cores exist. They are prevalent in the textile industry for holding fabric rolls, which prevents damage during shipping. In the printing world, cardboard cores provide a sturdy base for large rolls of paper, ensuring they remain undamaged. However, despite their benefits, many companies still do not fully leverage the advantages that cardboard cores offer.

While innovations in materials could enhance strength, there are limitations. Cardboard cores can absorb moisture, leading to structural weakness. This factor necessitates continuous improvement and reassessment to meet industry demands better. Understanding these challenges can propel the cardboard core industry forward.

Understanding Cardboard Cores: Definition and Composition

Cardboard cores are essential components in many industries. They are primarily made from recycled paper products. Their structure includes multiple layers of paper, which gives them strength. The composition ensures they are lightweight yet sturdy. This makes them ideal for various applications, from packaging to manufacturing.

We should consider the use of cardboard cores carefully. While they are often recyclable, not all forms of cardboard meet recycling standards. Data shows that around 90% of cardboard used in industrial applications can be recycled, but it’s crucial to check local guidelines. If the core is contaminated, it might not be suitable for recycling.

**Tip:** When disposing of cardboard cores, verify that they are clean and dry. This increases their chances of being recycled properly.

In terms of benefits, these cores offer cost-effectiveness. They reduce the weight of products, leading to lower shipping costs. However, buyers must also think about the environmental impact. Misuse of these products can lead to waste. Ensuring proper use is vital for sustainability.

**Tip:** Always opt for suppliers who prioritize sustainable practices. This choice can significantly influence the environmental impact of your operations.

Exploring Common Uses of Cardboard Cores in Various Industries

Cardboard cores are versatile tools widely used across various industries. They serve a crucial function in packaging, construction, and manufacturing. For example, in the textile industry, cardboard cores are essential for winding yarn. Reports indicate that the demand for cardboard cores is expected to grow by 4.5% annually, driven by the rise in eco-friendly packaging solutions.

In construction, these cores find use in insulation and creating structural supports. Their lightweight nature offers an accessible yet strong alternative to traditional materials. While they provide excellent performance, some companies face challenges in recycling practices. It often leads to unused materials that contribute to waste. A closer look at supply chains may reveal gaps in sustainability efforts.

Tips: Always consider local recycling options when disposing of cardboard cores. This can lead to better resource management. Streamlining processes can seem daunting. Focus on assessing each stage for potential improvements. Balancing cost and sustainability may be tricky. However, small changes can lead to significant benefits.

Advantages of Using Cardboard Cores: Environmental and Economic Benefits

Cardboard cores are often overlooked, yet they offer significant environmental and economic benefits. These cylindrical structures, typically used in packaging, have a lighter footprint than plastic or metal alternatives. They are made from recycled materials and are themselves recyclable. This means that using cardboard cores reduces waste and promotes sustainability.

On the economic side, manufacturers find cardboard cores cost-effective. They are cheaper to produce and transport. This leads to lower overall production costs, which can be beneficial for both small businesses and large corporations. However, some may argue that cardboard lacks the durability of other materials. This is an area that requires reflection. The balance between cost and quality is not always straightforward.

In many cases, companies need to assess their needs carefully. For instance, not all applications suit cardboard cores perfectly. Certain industries may still struggle with the material's limitations. Yet, the overall potential remains robust. As businesses evolve, re-evaluating material choices reflects a commitment to both economic efficiency and environmental responsibility.

Understanding Cardboard Cores: Their Uses, Benefits, and Applications

| Dimension | Details |

|---|---|

| Material Type | Recycled Paperboard |

| Common Uses | Shipping tubes, Carpet rolls, Textile rolls |

| Size Range | From 1 inch to 12 inches in diameter |

| Weight Capacity | Up to 500 lbs depending on the design |

| Environmental Benefits | Biodegradable and recyclable, reducing landfill waste |

| Economic Benefits | Cost-effective material compared to plastics or metals |

| Customization | Easily customizable for various applications |

| Application Industries | Packaging, Construction, Pulp and Paper, Arts and Crafts |

Applications of Cardboard Cores in Packaging and Manufacturing

Cardboard cores are essential components in packaging and manufacturing. They serve various functions across different industries. For instance, they are commonly used in the production of paper products, like rolls of tissue paper or cardboard sheets. Their ability to support weight while remaining lightweight is quite impressive.

In packaging, cardboard cores are not just functional; they can also enhance product presentation. They can act as a stable base for wrapped items. Brands often use colored or printed cores to add visual appeal. This attention to detail can attract customers, influencing their purchasing decisions. However, some may overlook the importance of a simple, clean design.

Moreover, the applications extend beyond packaging. Industries like textiles rely on cardboard cores for efficient material storage. They keep large fabric rolls tidy and prevent damage. Yet, not all cores are created equal. Some can be flimsy, failing to meet industry standards. Reflecting on this inconsistency, manufacturers must improve quality control to ensure reliability in their products.

Innovative Trends and Future Directions for Cardboard Core Utilization

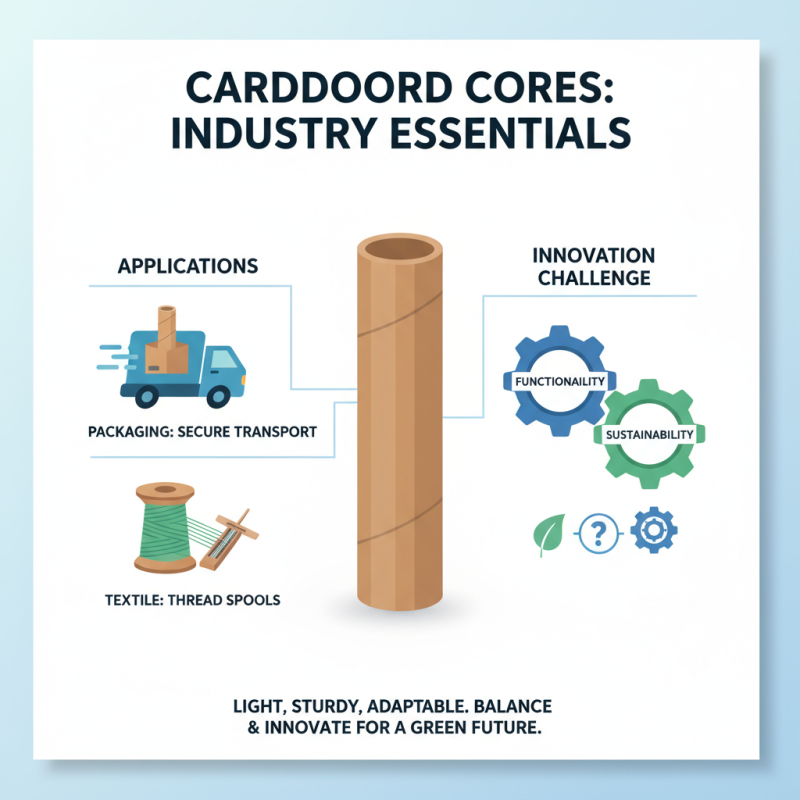

Cardboard cores are emerging as essential components in various industries. Their lightweight yet sturdy structure allows for diverse applications. In packaging, these cores often ensure items remain secure during transport. In the textile industry, they serve as spools for threads, streamlining production processes. However, manufacturers must continuously seek ways to innovate. The challenge lies in balancing functionality and sustainability.

Recent trends show increased interest in eco-friendly options. Cardboard cores can be produced from recycled materials, reducing environmental impact. Brands are exploring biodegradable coatings that enhance durability while remaining eco-conscious. This direction could redefine core production standards. Still, not all innovations hit the mark. Some experiments may lead to functionality issues or higher costs, requiring careful evaluation.

Future applications are promising but complex. Industries are testing new forms, such as collapsible and customizable cores. These may cater to specific needs, but practicality remains a key concern. While the potential is vast, firms must reflect on user feedback and performance metrics. This iterative process ensures that cardboard cores fulfill their purpose effectively.

Related Posts

-

Why Industrial Cardboard Tubes Are the Sustainable Choice for Packaging With 30 Percent Less Material Waste

-

Unlocking Efficiency: Why Cardboard Tubes for Shipping Are the Future of Sustainable Packing Solutions

-

Top 5 Creative Uses for Cardboard Tubes in Your Crafts Projects

-

What is Cardboard Tube Packaging and How it Benefits Your Business

-

How to Use Cardboard Tubes for Crafts Fun and Creative DIY Ideas

-

Top 10 Cardboard Tubes for Shipping You Need to Know About

© 2025 Cardboard Tubes | Registered in England and Wales.

Company Number 2402078