What is the Purpose of Packaging Tubes in Modern Industries?

In the fast-evolving world of modern industries, packaging tubes play a crucial role in product delivery. According to Dr. Jane Harper, a leading expert in packaging technology, "Packaging tubes are essential for protecting products and enhancing brand presence." This statement highlights the dual purpose these tubes serve.

Packaging tubes provide a protective barrier against external elements. They ensure that products remain safe during transport and storage. However, the industry faces challenges in balancing sustainability and functionality. Some materials used are not eco-friendly, sparking debates on environmental impact.

Moreover, effective design is vital in attracting consumers. An eye-catching tube can make a difference on retail shelves. Yet, companies often overlook the importance of user experience. The ease of opening and disposal can affect customer satisfaction. Addressing these aspects can lead to improvements in the packaging tubes market, benefiting both producers and consumers.

The Role of Packaging Tubes in Product Safety and Preservation

Packaging tubes play a critical role in ensuring product safety and preservation. In many industries, they protect contents from damage and contamination. For example, a report from the

Flexible Packaging Association states that flexible packaging contributes to reduced food waste by up to

30%. This flexibility allows products to maintain freshness longer, extending shelf life.

Moreover, packaging tubes often feature tamper-evident seals. These seals ensure that consumers can trust the safety of the product. A study by the

Packaging Efficiency Group indicates that nearly

50% of consumers consider safety a top priority when purchasing packaged goods. This shows the importance of effective packaging in building consumer confidence.

However, there are challenges. Some packaging tubes are not easily recyclable. This raises questions about environmental impact. According to the

World Packaging Organization, sustainable packaging solutions are becoming urgent. Many companies are now exploring alternative materials to reduce plastic waste. Emphasizing

innovative designs might address safety without compromising ecology.

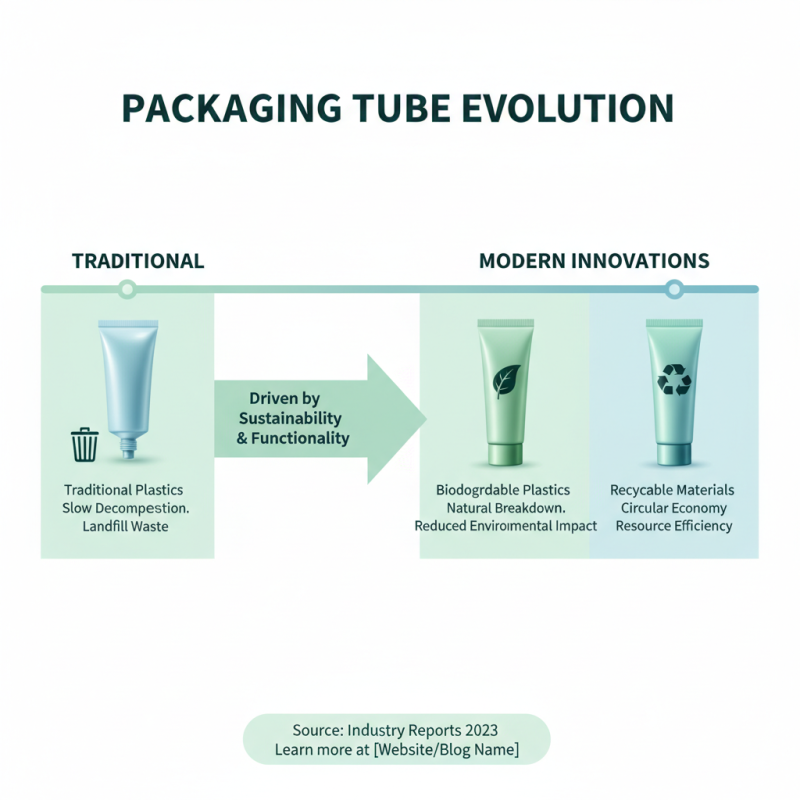

Innovative Materials Used in Modern Packaging Tubes

Packaging tubes have evolved significantly in recent years. Modern industries now use innovative materials that enhance both functionality and sustainability. For instance, biodegradable plastics are gaining traction. These materials break down naturally, reducing landfill waste and environmental impact.

Another exciting development is the use of aluminum for packaging tubes. Aluminum is lightweight and recyclable. It provides an excellent barrier against moisture and air, preserving product integrity. Some companies experiment with plant-based materials. These alternatives may not yet be as durable but offer potential for eco-friendly packaging solutions.

However, challenges remain. Not all innovative materials are cost-effective. Balancing price and sustainability is crucial for businesses. Additionally, consumer awareness about packaging materials continues to grow. Educating customers about the benefits of these innovations is essential for market acceptance. The industry must find ways to communicate the value of sustainable choices effectively.

Sustainability and Eco-Friendly Practices in Tube Design

Packaging tubes have gained attention for their role in sustainability. Modern industries are increasingly adopting eco-friendly practices in tube design. In a 2021 report by Smithers, the global market for sustainable packaging is projected to reach $500 billion by 2026. This shift reflects a growing demand for environmentally responsible materials.

Many tube manufacturers are exploring biodegradable and recyclable options. For instance, using materials like post-consumer recycled plastics can significantly reduce waste. Yet, not all tubes meet these criteria. A recent study found that only 30% of packaging tubes are recyclable in current waste management systems. This indicates room for improvement in design and material selection.

Attention to design elements also influences sustainability. Multi-layer tubes, often used for better preservation, complicate recyclability. They can be 30% less eco-friendly than single-layer options. Innovations are needed to balance functionality with ecological impact. Striving for better designs is essential. However, the industry must reflect on its current practices. There’s still a long way to go in making packaging tubes truly sustainable.

Consumer Appeal: Aesthetic and Functional Aspects of Packaging Tubes

Packaging tubes play a crucial role in modern industries. Their design combines both aesthetics and functionality. A well-designed tube can attract customers instantly. Bright colors and unique shapes catch the eye on store shelves. A tube can tell a story, reflecting the product inside. The right packaging can evoke emotions and connect with consumers.

Functionality is equally important. Tubes protect the product they contain. A sturdy tube can prevent spills and leaks. Many consumers prefer easy-to-use packaging that allows for precise application. For instance, a squeeze tube is handy for creams and gels. Yet, not all designs achieve this blend perfectly. Some tubes can be difficult to open or dispense. This can frustrate users and lead to wasted product.

Sustainability has also entered the conversation. Consumers are increasingly seeking eco-friendly options. A tube made from recycled materials can appeal to the environmentally conscious. However, achieving this while maintaining quality can be challenging. Companies face pressure to innovate without compromising product safety. Balancing aesthetic appeal, functionality, and sustainability is an ongoing journey for many brands.

Purpose of Packaging Tubes in Modern Industries

The Manufacturing Process and Technologies Behind Packaging Tubes

Packaging tubes play a crucial role in various industries. They ensure product safety and enhance user experience. The manufacturing of these tubes is intricate, involving multiple technologies. Generally, the process starts with raw materials like aluminum or plastic. These materials are chosen for their protective qualities.

Once selected, the materials undergo shaping. This often involves extrusion or molding, creating the desired tube form. Next, the tubes are filled with the product. This step requires precision to avoid overflow or contamination. After filling, sealing is vital to maintain freshness. Different sealing methods may be used, depending on the product type.

Tips: When choosing packaging tubes, consider the end user's ease of use. Test different designs to find the best fit. Small adjustments in the manufacturing process can lead to significant improvements. Always aim for quality control; even minor defects can affect user perception.

Moreover, innovations in technology are changing the game. Machines are becoming more efficient, reducing waste. Automation helps in speeding up production while maintaining consistency. However, it's important to reflect on sustainability. Balancing efficiency with environmental impact should be a priority. Choose materials that minimize environmental harm.

What is the Purpose of Packaging Tubes in Modern Industries?

| Material | Application | Benefits | Production Technology |

|---|---|---|---|

| Plastic | Cosmetic Products | Lightweight, flexible, and customizable. | Extrusion and Injection Molding |

| Aluminum | Food and Beverage | Excellent barrier properties and recyclability. | Aluminum can forming and filling |

| Paperboard | Pharmaceuticals | Sustainable, printable, and cost-effective. | Die-cutting and folding |

| Glass | Luxury Products | Premium look, inert material, and reusable. | Blow molding and molding |

| Compostable Materials | Organic Products | Eco-friendly, biodegradable solutions for consumers. | Bioplastic molding and laminating |

Related Posts

-

Top Uses for Cardboard Postal Tubes in 2025: Shipping, Storage, and More!

-

The Future of Delivery Packaging Innovations Shaping Sustainable Shipping Solutions

-

How to Create Amazing Crafts with Cardboard for All Ages

-

Why Industrial Cardboard Tubes Are the Sustainable Choice for Packaging With 30 Percent Less Material Waste

-

The Ultimate Guide to Discovering the Benefits of Bulk Cardboard for Sustainable Packaging

-

Understanding Cardboard Cores Their Uses Benefits and Applications

© 2025 Cardboard Tubes | Registered in England and Wales.

Company Number 2402078