What is Industrial Cardboard and its Benefits for Packaging Solutions

Industrial cardboard has emerged as a crucial material in the packaging sector, driven by the increasing demand for sustainable and efficient packaging solutions. According to a report by Smithers Pira, the global market for corrugated cardboard packaging is expected to reach 330 billion USD by 2024, reflecting a compound annual growth rate (CAGR) of 3.8%. This growth is largely attributed to the rising consumer preference for eco-friendly packaging options that not only reduce environmental impact but also enhance supply chain efficiency.

The versatility and durability of industrial cardboard make it an ideal choice for a variety of applications, ranging from shipping to point-of-sale displays. A study conducted by the Freedonia Group highlighted that corrugated cardboard accounted for over 50% of the total paperboard production in 2021, indicating its dominance in the packaging industry. The lightweight yet robust nature of industrial cardboard also contributes to lower transportation costs and reduced carbon emissions, aligning with the global shift towards sustainable practices. As businesses increasingly prioritize sustainability, the adoption of industrial cardboard as a primary packaging solution is likely to continue its upward trajectory, offering numerous benefits to manufacturers and consumers alike.

Definition and Composition of Industrial Cardboard in Packaging

Industrial cardboard is a versatile and sustainable material used extensively in packaging solutions. Its composition primarily consists of cellulose fibers sourced from wood pulp, which gives it a lightweight yet sturdy structure. According to the Fiber Box Association, in the United States alone, over 95% of all consumer products are shipped in corrugated packaging made from industrial cardboard, highlighting its significance in the logistics and supply chain industries.

The composition of industrial cardboard typically includes multiple layers, which enhance its strength and durability. The outer layers, known as liners, are crafted from recycled paper, while the inner layer—often referred to as the flute—provides cushioning. This multi-layered approach not only improves resistance to crushing and bending but also contributes to insulation, making it ideal for protecting a wide range of products during transit. Recent studies conducted by Smithers Pira estimate that the global demand for corrugated cardboard packaging will reach 240 million tons by 2024, driven by the increased need for sustainable and efficient packaging solutions.

Moreover, industrial cardboard's recyclability adds to its environmental benefits. The Paper and Forest Products report indicates that corrugated cardboard currently has a recycling rate of around 88% in North America, making it one of the most recycled materials in the region. This high recovery rate not only conserves natural resources but also reduces landfill waste, aligning with the growing emphasis on eco-friendly practices in packaging industries worldwide.

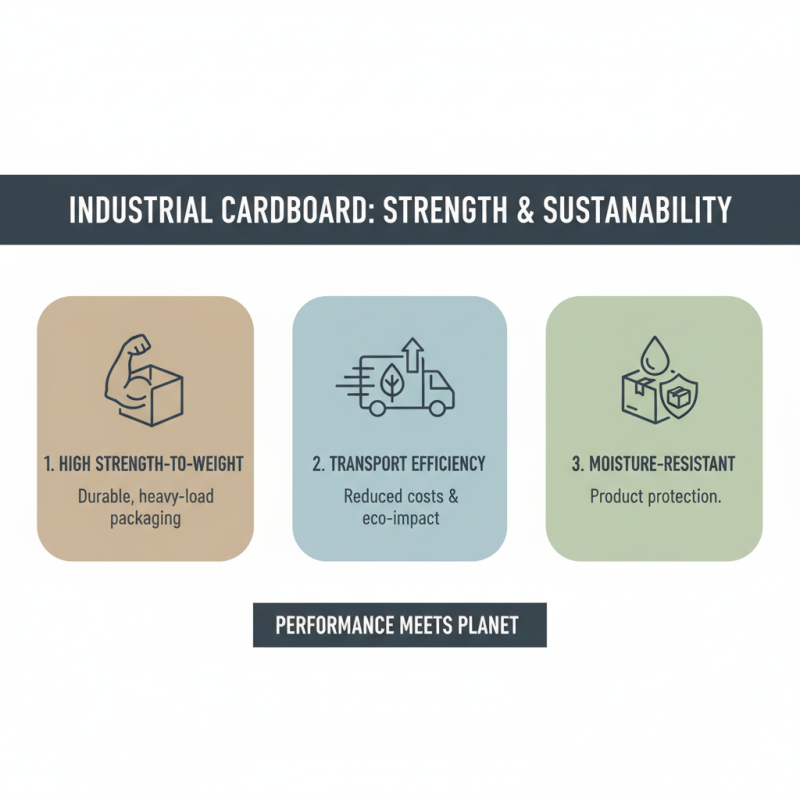

Key Characteristics of Industrial Cardboard for Optimal Performance

Industrial cardboard is a high-performance material designed to meet the demanding needs of various industries. One of its key characteristics is its impressive strength-to-weight ratio, allowing for durable packaging solutions that can withstand heavy loads while remaining lightweight. This contributes significantly to transportation efficiency, reducing shipping costs and minimizing environmental impact. Additionally, industrial cardboard is often moisture-resistant, which protects products from damage during storage and transit.

When selecting industrial cardboard for packaging, consider its thickness and layering. Thicker cardboard offers enhanced protection for fragile items, while multi-layered options provide extra cushioning. It’s also important to choose cardboard with a smooth surface for easy printing and branding, ensuring your packaging not only protects the product but also serves as an effective marketing tool.

**Tips:** Always test different cardboard grades to find the optimal balance between durability and weight for your specific applications. Additionally, consider the recyclability of the cardboard, as using eco-friendly materials can enhance your brand's sustainability efforts and appeal to environmentally-conscious consumers.

Statistical Insights: Market Growth and Demand for Industrial Cardboard

The industrial cardboard market has been experiencing significant growth, driven by increasing demand for sustainable packaging solutions across various sectors. As industries move towards eco-friendly practices, cardboard's recyclable and biodegradable properties make it a preferred material for packaging. According to recent statistical insights, the global market for industrial cardboard is projected to expand at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth reflects a broader trend where businesses prioritize sustainability in their supply chains, leading to an uptick in the adoption of cardboard packaging.

Additionally, the rising e-commerce sector has fueled the demand for industrial cardboard due to its lightweight, durability, and versatility. With online shopping becoming a staple for consumers, packaging that ensures product safety during transit while also being cost-effective is essential. Recent analyses indicate that the demand for industrial cardboard is expected to surge as businesses seek smarter packaging solutions that align with both consumer preferences and environmental concerns. This trend not only illustrates the material's adaptability but also highlights a significant shift towards responsible packaging practices in the market.

What is Industrial Cardboard and its Benefits for Packaging Solutions

| Dimension | Statistic | Comment |

|---|---|---|

| Market Size (2023) | $35 Billion | Growing demand in e-commerce packaging. |

| Annual Growth Rate (CAGR 2023-2028) | 7.5% | Strong growth driven by sustainability trends. |

| Market Share by Application (E-commerce) | 45% | Largest application segment for industrial cardboard. |

| Recycling Rate | 85% | High recyclability supports sustainable practices. |

| Average Weight per Unit | 400 grams | Standard weight across common packaging styles. |

| Preferred Thickness | 5 mm | Optimal for durability and protection. |

Sustainability Benefits of Industrial Cardboard in Packaging Solutions

Industrial cardboard is increasingly recognized for its sustainability benefits in packaging solutions. Made from renewable resources, industrial cardboard is predominantly crafted from recycled materials, contributing to a circular economy. This eco-friendly alternative significantly reduces waste, as it can be recycled multiple times, minimizing the demand for virgin materials. By choosing industrial cardboard for packaging, companies can lower their carbon footprint and promote responsible sourcing practices, which resonate with environmentally conscious consumers.

Additionally, the biodegradable nature of industrial cardboard plays a vital role in its environmental advantages. Unlike plastic packaging, which can take centuries to decompose, cardboard breaks down naturally over a short period, significantly reducing landfill contributions. This characteristic not only helps in conserving the environment but also meets the growing regulatory demands for sustainable packaging solutions. As businesses look to enhance their sustainability profiles, adopting industrial cardboard can be a strategic move towards more eco-friendly practices, aligning with consumer preferences for greener products.

Innovative Applications of Industrial Cardboard Across Various Industries

Industrial cardboard is rapidly gaining traction in various sectors, thanks to its versatility and sustainability. With growing environmental concerns, industries are increasingly turning to innovative applications of industrial cardboard for packaging solutions. According to a report by Smithers Pira, the global market for corrugated packaging alone is projected to reach $300 billion by 2024, underscoring the demand for materials that are both cost-effective and environmentally friendly.

In sectors like electronics and automotive, industrial cardboard is being utilized for protective packaging. It provides excellent cushioning and protection against shocks during transportation. Additionally, industries such as food and beverage are utilizing custom-designed cardboard packaging that not only preserves product freshness but also enhances visual appeal on retail shelves. A study by Technavio estimates that demand for eco-friendly packaging will grow by over 20% annually, indicating a significant shift towards sustainable alternatives like industrial cardboard.

Moreover, industrial cardboard is making waves in the e-commerce industry, where lightweight yet durable packaging solutions are critical. The ability to customize sizes and shapes means that companies can reduce waste and optimize shipping costs. Research from the Packaging Industry Association reveals that e-commerce packaging, including cardboard options, is expected to grow by 25% through 2025, reflecting the broader trend toward more sustainable packaging practices across industries.

Benefits of Industrial Cardboard in Packaging Solutions

Related Posts

-

Maximizing Profitability in the Industrial Cardboard Sector at the 2025 China Import and Export Fair

-

How to Create Amazing Crafts with Cardboard for All Ages

-

Exploring the Rise of Sustainable Kraft Tubes: Why Brands Are Making the Switch in 2023

-

10 Best Paperboard Tube Packaging Solutions for Eco Friendly Products

-

Essential Tips for Choosing the Right Postal Packaging to Ensure Safe Shipments

-

10 Best Postal Tubes for Secure Document Shipping in 2023

© 2025 Cardboard Tubes | Registered in England and Wales.

Company Number 2402078