How to Choose the Best Stainless Steel Woven Wire Mesh?

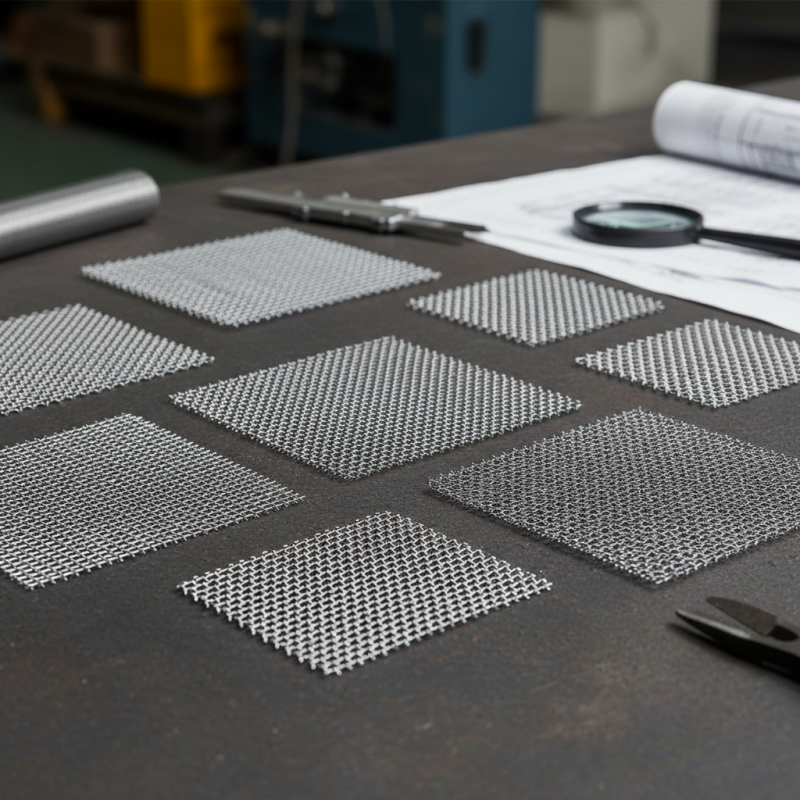

Choosing the right stainless steel woven wire mesh can be challenging. This material is known for its durability and versatility. It finds applications in various industries, from construction to food processing.

When selecting stainless steel woven wire mesh, consider several factors. The wire diameter, mesh opening, and weave type matter. Some meshes provide better filtration, while others offer strength. Exploring these options is essential for making the best choice for your project.

It's crucial to reflect on your specific needs. Sometimes, the ideal mesh may not be immediately apparent. Keep in mind the environment where the mesh will be used. Certain conditions may wear down the material faster than expected. Taking these details into account ensures a more informed decision.

Understanding Stainless Steel Woven Wire Mesh Types and Standards

When considering stainless steel woven wire mesh, understanding its types and standards is crucial. Woven wire mesh comes in various designs. Each type caters to specific applications, like filtration, sieving, or reinforcement. The choice of weave pattern affects the wire mesh's strength and flexibility, which influences its final use.

Standards for stainless steel mesh vary by region and industry. Common specifications include ASTM and ISO standards. These guidelines ensure the durability and safety of the material. It is important to check these standards before making a purchase. Not doing so could lead to using inferior materials.

Selecting the right mesh can be tricky. Mistakes happen; some may overlook the importance of wire diameter. The size affects not just strength but also the mesh's ability to filter specific particles. It can be frustrating when an unsuitable mesh is chosen, leading to costly replacements. Thus, it’s essential to clarify your requirements before deciding.

Key Factors to Consider When Selecting Stainless Steel Materials

When choosing stainless steel woven wire mesh, several key factors come into play. The type of stainless steel is crucial. Different grades offer various levels of corrosion resistance, durability, and temperature tolerance. 304 stainless steel is common, while 316 provides better protection against saltwater environments. Consider where the mesh will be used. Outdoor applications often require higher resistance.

Tip: Evaluate the environment before deciding. If your mesh will face harsh conditions, opt for a higher grade.

Another important factor is the wire diameter and mesh opening size. A thicker wire can enhance strength, while smaller openings may be necessary for filtration purposes. Think about your specific needs. A fine mesh may restrict airflow but can improve protection from small particles.

Tip: Balance strength and clarity. A tightly woven mesh offers fewer gaps but can be less efficient in certain air flow scenarios.

Also, consider the manufacturing process. Different weaving techniques impact the final product. For example, a plain weave is typically stronger, while a twill weave offers flexibility. Assess how much flexibility you need. It's easy to overlook, yet it can make a significant difference.

Mesh Size and Opening Shapes: Impact on Functionality and Applications

When selecting woven wire mesh, mesh size and opening shapes greatly affect functionality. Different applications require specific sizes. A large opening allows for easy flow, while a small one captures fine particles. Consider the materials being processed. For coarse materials, larger openings work best. But for filtration purposes, smaller openings are essential.

The shape of the openings also plays a crucial role. Square openings provide even distribution and consistent flow. Round openings, on the other hand, can create more turbulence, which may not always be desirable. In some cases, elongated or slotted openings can enhance strength while still allowing for adequate flow. It's important to assess what you need from your mesh before making a choice.

Ultimately, the best mesh selection might need some trial and error. Assessing performance in real-world conditions can reveal unexpected challenges. For instance, a mesh that looks perfect on paper may not function as well under pressure. It's crucial to reflect on tests and feedback to refine your choices.

Evaluating Durability and Corrosion Resistance of Stainless Steel Mesh

When choosing stainless steel woven wire mesh, durability and corrosion resistance are critical factors. Stainless steel is favored for its strength. Still, not all types perform equally well under harsh conditions. The mesh composition affects its resilience to rust and wear.

Different stainless steel grades can significantly impact performance. Some may resist corrosion better than others. For example, a lower grade may not withstand exposure to saltwater. This could lead to faster deterioration over time. It's essential to assess the environment where the mesh will be used. High humidity or corrosive substances require a better quality mesh.

Mesh installation can also affect its lifespan. Improper handling may lead to weak points, increasing vulnerability. Regular maintenance is often overlooked but can prolong the lifespan. Simple cleaning routines can eliminate build-up and prevent corrosion. In conclusion, careful evaluation of materials and conditions is necessary for long-lasting results.

Durability and Corrosion Resistance of Stainless Steel Woven Wire Mesh

Cost Considerations and Supplier Selection for Quality Mesh Products

When selecting stainless steel woven wire mesh, cost considerations play a pivotal role. The price of such mesh can vary significantly based on material, weave type, and application. According to a report by the International Wire and Wire Products Association, the cost per square foot can range from $2 to $10, depending on these factors. Understanding pricing can prevent overspending on unnecessary features.

Supplier selection is equally important. Quality often hinges on the supplier's reputation and experience. You should research potential suppliers extensively. Look for reviews and case studies. It’s crucial to ensure that the supplier meets industry standards. For example, the American Society for Testing and Materials (ASTM) provides guidelines for material quality that many top suppliers adhere to. Failure to choose the right supplier may result in receiving subpar products, affecting the entire project.

Additionally, consider asking for samples before committing to a large order. This allows you to gauge the mesh quality firsthand. Keep in mind that cheaper options may not perform as expected. In some cases, sacrificing quality for lower costs can lead to higher expenses down the line. Reflect on these aspects thoroughly as you navigate the selection process.

How to Choose the Best Stainless Steel Woven Wire Mesh? - Cost Considerations and Supplier Selection for Quality Mesh Products

| Mesh Type | Aperture Size (mm) | Wire Diameter (mm) | Material Grade | Cost per Square Meter ($) | Supplier Rating (1-5) |

|---|---|---|---|---|---|

| Plain Woven | 1.0 | 0.5 | 304 | 25 | 4 |

| Dutch Weave | 0.5 | 0.3 | 316 | 30 | 5 |

| Square Woven | 2.0 | 0.6 | 304 | 27 | 4 |

| Twill Woven | 1.5 | 0.7 | 316 | 35 | 5 |

| Specialty Mesh | 0.8 | 0.4 | 304 | 40 | 3 |

Article Source:

© 2025 Cardboard Tubes | Registered in England and Wales.

Company Number 2402078